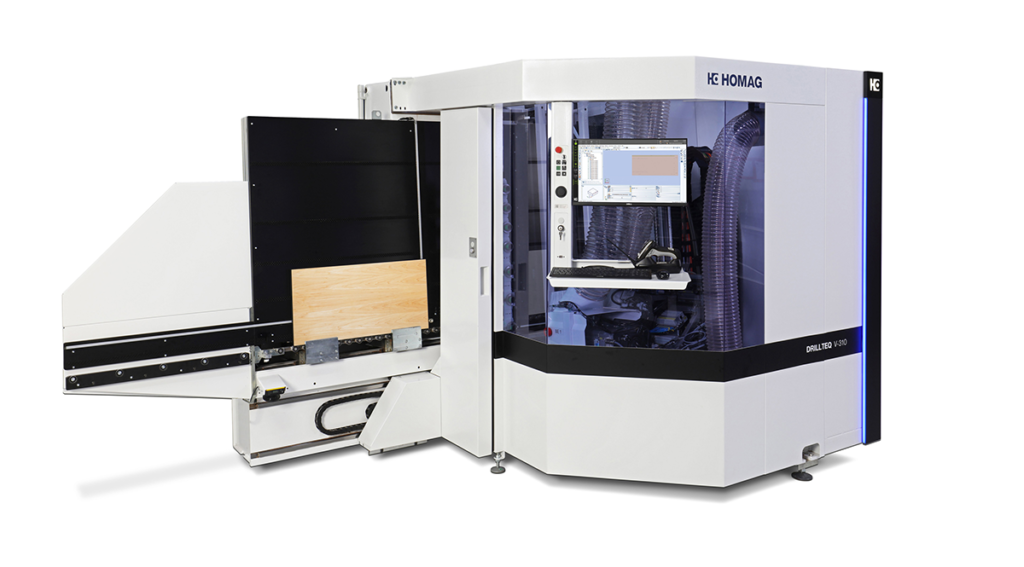

If space is a major issue in your production facility then the latest vertical CNC processing centre from HOMAG, the DRILLTEQ V-310, could be just what you’re looking for. The design brief for this advanced machine was to incorporate as much functionality as possible in as small a space as possible.

“The new DRILLTEQ V-310 vertical CNC really is a space miracle,” claims HOMAG UK managing director, Simon Brooks. “With a footprint of just 11 m2 it offers more drilling (up to 45 drilling spindles), more grooving (two groove saws), a dowel unit and more trimming than any other machine in its class. Despite the compact nature of the V-310, it can still handle panels up to 1,250 mm in width and 80 mm in thickness.

“Attention has also been focused on energy-efficient processing, with the vacuum-free clamping system not only saving energy, but also providing fast setup times.

“A number of ‘plug & play’ automation add-ons are available to extend machine running time, including the FEEDBOT D-310 robot feeder and a return conveyor. These additions virtually eliminate manual parts handling and reduce the need for more machine operators.”

A wide range of configurations for any application

The DRILLTEQ V-310 offers a great choice of drilling heads including a twin head configuration which can perform row hole drilling in half the time on certain panels. The machine can be specified for routing with automatic tool changing in the standard three axis format or additionally, it is possible to choose a four axis model to permit the use of aggregates for horizontal routing, sawing, corner notching and even traced surface routing. As a further option, it is possible to select an automatic dowel gluing and insertion unit to allow panels to be fully processed within one cycle.

HOMAG’s safety concept

HOMAG’s safeScan technology enables optimum interaction between operator and machine. At the infeed and outfeed there is a scanner which is triggered as soon as the machine operator approaches to within 900 mm of the loading or unloading area.

A highly efficient feature of the technology is the automatic continuation of production as soon as the operator leaves the area. No confirmation or restart of processing is required due to the Autoquit feature.

Next generation control with powerTouch 2

Controlling the DRILLTEQ V-310 is even faster and more intuitive with the latest control system powerTouch 2. The new, modern design has a clear structure with an innovative touch operation.

Compared to the previous version, you can achieve a time saving of up to 30%. This is possible due to new features, such as automatic word completion, a pop-up keyboard that can be kept open and Windows-like functions, such as the selection of common actions directly via the start button.

Manage tools easily and quickly with the twinio web app

With the twinio app tool management is easy and quick. Different functions in the app ensure an overview of the statuses and storage locations of the tools is always available. Important maintenance, such as tool sharpening is simple to schedule with just one click.

The app provides historical data in a graphical format of how tools have performed after previous sharpening cycles, presenting information to improve future performance.

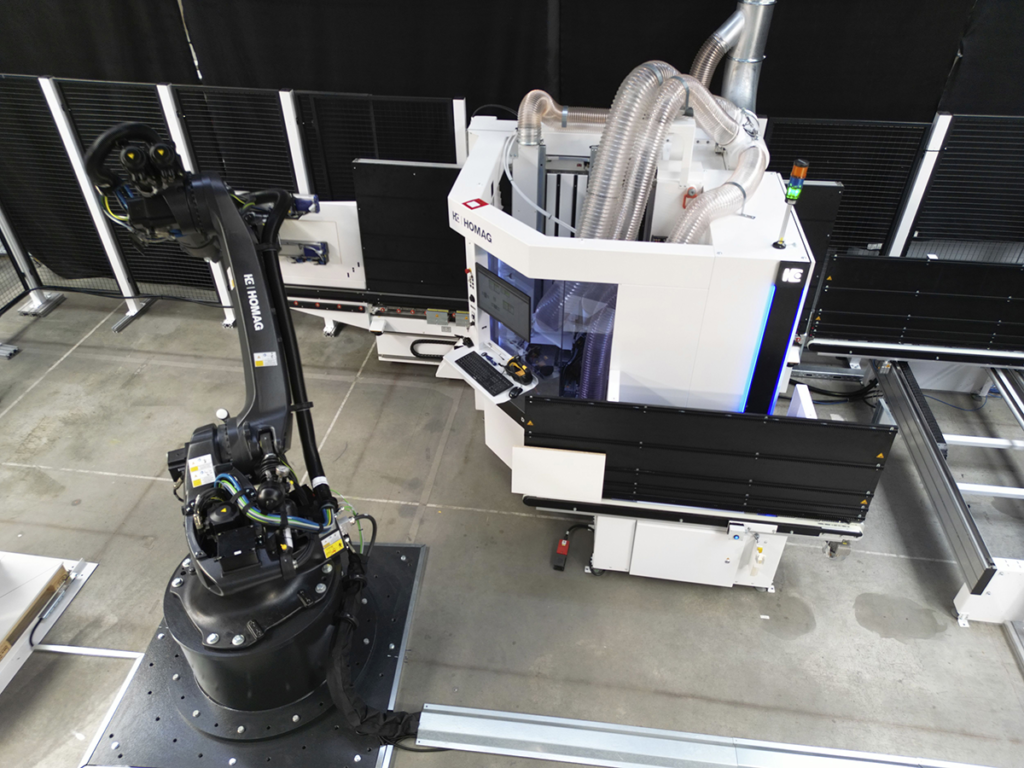

Automation with the FEEDBOT D-310 robot

Automating the material handling has many benefits including low maintenance operation, highly flexible production and the elimination of health and safety issues that come with manual handling.

With a sensitive floating crosshead to ensure gentle handling of parts, the FEEDBOT D-310 can handle large variances in workpiece size. It has a ‘plausibility check’ which compares data from the control to the actual part. Using woodFlex the setup of the complete cell (CNC and robot) can be handled automatically with visual confirmation on screen.

Utilised in a cell, the FEEDBOT increases overall productivity. It does not have to take a break, it can work around the clock and ensures consistently high quality results. It saves a lot of time, reducing the workload for production staff. This enables the workforce to be moved to more value-added activities in the manufacturing process.

In conclusion, Simon Brooks said: “The DRILLTEQ V-310 is a significant milestone in the design of small-footprint vertical CNCs. The number of functions incorporated in this compact model are amazing. When it was presented to the trade last year it caused a real buzz and no doubt there will be high demand for it in the UK market.”

For more information or a demonstration of the DRILLTEQ V-310 or any other HOMAG machinery and software, please contact Adele Hunt at HOMAG UK on 01332 856424.

T: 01332 856500