Surface treatment plays an increasingly crucial role in raising the aesthetic and practical quality of a piece of furniture, a fixture, or a wooden floor… This is why SCM was the first to believe in the importance of expanding its extensive range of products and services for machining wood, even with exclusive solutions and skills in terms of Superfici finishing, a historical brand for designing, developing, and manufacturing complete machines and plants for painting.

VALTORTA BRAVOROBOT

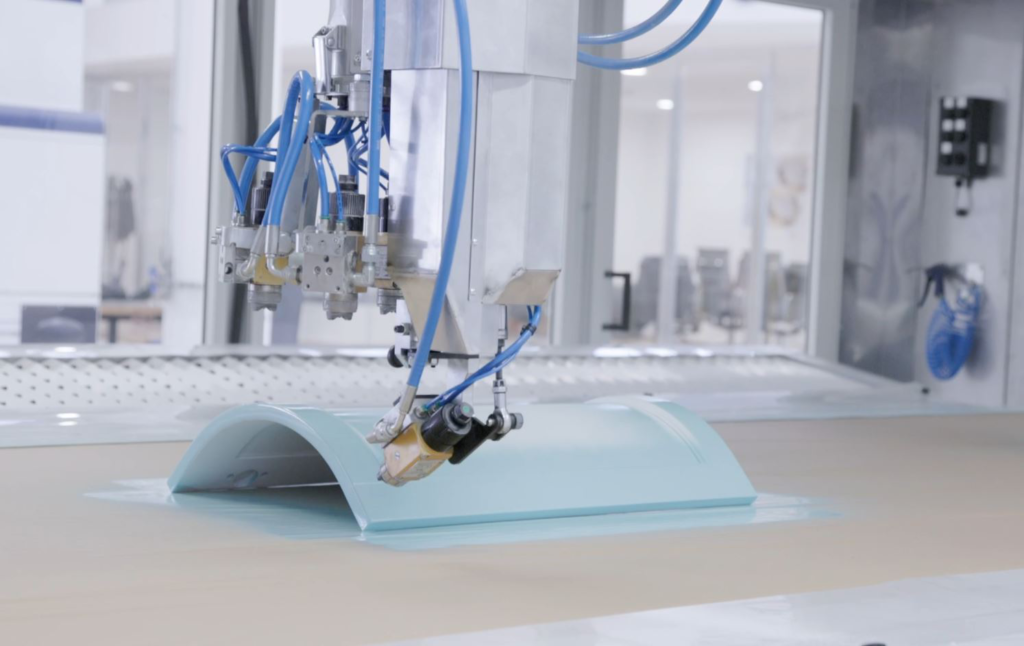

The Superfici Valtorta Bravorobot. This Cartesian spraying robot is part of the Superfici DNA because it was able to evolve over time, thanks to constant innovation and technological improvement. The main idea behind the Bravorobot is to replicate the movements of an artisan craftsman and to join together two of the most important features for the perfect finishing: consistency and delicacy. Consistency, expected from a machine even after prolonged activity, not only means reliability on the final product, but also less waste. Delicacy, expected from a craftsman, is ensured thanks to the 5-axis system, which allow the spraying system to freely move, reaching all the parts even of complex geometries.

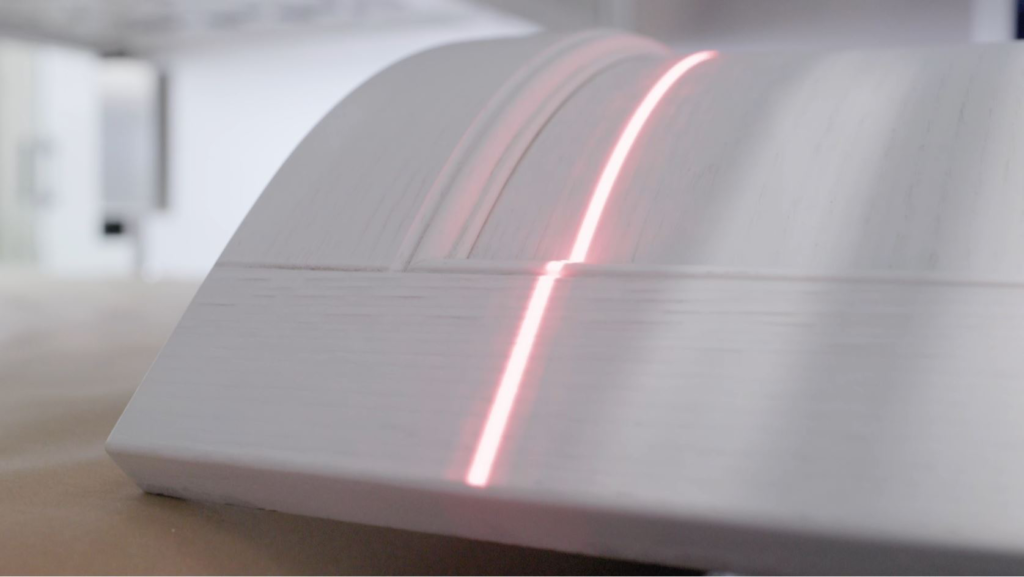

The machine is able to recognise characteristics and geometries thanks to the 3D scanner at the entrance of the infeed. The data, related to size, position, and shape of each panel of the workpiece, is sent to the electronic control of the machine. The advanced Superfici software translates this information into movements for the arm and, in combination with the generated data, gives the perfect spraying path to the arm. The function is very intuitive and user-friendly to set. It involves optimising the movement of the arm in terms of production even for the most complex forms.

What really plays a fundamental role in the quality and gives the machine a boost to the Bravorobot is the ability to tilt and position the robotic arm so that the guns can be adapted for edges and nonplanar part geometries.

The cabin ensures the perfect quality of air inside the machine. This is really important not only for the correct management of any overspray but also to reduce the dirt and dust particles that could enter and ruin the status of the painting. The filtering system consists of two filtering elements. A cardboard filter that retains the majority of the paint particles, sub sequentially a filter made of synthetic material collects the finest particles. Optionally, is possible to have the machine with a water filtration system. Water layers are generated and maintained on the sides of the conveyor: the air passing through these layers deposits the solid particles of paint contained therein. The water curtains are obtained using the continuous recirculation of water contained in two special side tanks, connected to each other. Furthermore, the machine has a full-size filtering roof in the spraying cabin to achieve perfect control of the overspray and reduce turbulences.

Applications

The main aspect we need to focus on while talking about the Bravorobot, is FLEXIBILITY! The applications are countless and there is no real limit to the shapes and the geometry complexity of the parts that it can paint. Thanks to the 3D camera at the infeed of the chamber, the panels are scanned in three dimensions, and the software can elaborate the best paint trajectory possible. But even the best trajectory can’t be achieved without a flexible arm that can follow it; there comes a robotic arm with 5 axes, capable of complex movements in all dimensions. Bravorobot is the perfect solution for panels that have various surface faces even panels with rectangular shapes and grooves; it shines through with complex tasks compared to other spraying machines.

It paints not only the grooves but also j shapes and curved panels, and it does it always without reducing the application quality.

The Bravorobot is not only suitable for painting all kinds of materials (wood, glass, composite materials, .. ) but also for glue application: tuning the guns and the feeding system makes it possible to adapt it (the Bravorobot) to the glue’s specific characteristics.

www.scmgroup.com