Most purchasers of modern wood-waste burning equipment want one supplier to provide a “turn- key” solution. For Ranheat they even supply the mortice lock and key to the plant room. (as well as making the plant room)

Chris Franklin MD at Ranheat Engineering Ltd., a leading UK manufacturer of wood combustion equipment, continues his series of exclusive articles for Panel and Joinery Production. This issue he looks at the complete range of products made “in-house” by Ranheat.

“Many customers want us to undertake the complete project, from getting planning consent for the chimney, chimney height approval and local authority permits. We even make the buildings to house the equipment complete with ventilation panels and access doors.”.

Ranheat started designing and manufacturing its own range of buildings over 40 years ago. Originally called “transcons” pre-wired and pre-plumbed, made of steel rather than the customer making a wooden “shed” building that is a fire risk and often not a cheap solution.

Ranheat have used standard shipping containers, but they need a metal floor and often are not big enough to get the equipment in. As well as all of the building and mechanicals Ranheat also make all of their control panels in their purpose-built electrical department.

Most electrical problems that occur with any system are in the control panel. Because the panels are made in-house the Ranheat electricians know every wire they have installed and more importantly labelled. Adequate room is left for access, and they even have a light fitted to make working on the panel easier, once installed.

As well as the control panel Ranheat also undertake the complete mechanical and electrical installation on site.

Ranheat use flanged and welded pipework that is fabricated off site at the factory in Northampton. This avoids the need for any “hot work” on site. Heaters are delivered mounted on a frame and pre-wired and pre-plumbed and generally attached to the steel portal frame. The buildings are surveyed often using a 3-D optical scanner that produces an accurate 3-D drawing of the factory to avoid clashes with other services such as extraction ducting, lighting, and compressed air.

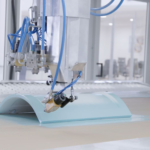

Ranheat also make the boilers and warm air heaters in-house. Each installation is unique but also similar to the ones before. This gives flexibility to the designers and the project engineers but helps simplify matters for the manufacturing team. Similar but not the same.

Ranheat also make the heat exchangers, combustion systems and flue gas filtration systems needed to meet the stringent emission regulations that now prevail.

Larger boilers are made in Denmark by Danstoker A/S. Ranheat still make all of the ancillary equipment for the larger systems at its factory in Northampton.

Ranheat also make spares and service and repair other makes of woodburning boilers and heaters.

For further information on all types and sizes of Industrial Woodburning equipment from 150 kW upwards contact Ranheat

T: 01604 750005