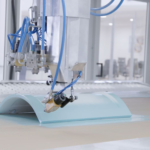

Introducing the new Power-Pin from Holz-Her. Launched at LIGNA 2023, this state-of-the-art drilling and dowel insertion machine is the perfect complement to nesting. With a horizontal drilling aggregate and a dowel insertion unit as standard, it eliminates the need for manual dowel insertion after CNC machining – presenting huge cost and time-saving benefits. Here’s how…

Flexible machining:

Suitable for use with workpieces from 60mm-2600mm in length, widths of 150mm for both horizontal and vertical machining and thickness of 12mm-60mm, the Power-Pin offers adaptable workpiece sizing.

Compact size:

Designed to incorporate all aggregates and storage tanks in the machine, the Power-Pin has a footprint of just 4m³ and an overall height of just 1755 mm (2095mm with the machine lid open). The space on the lid has also been cleverly designed to offers storage space for workpieces and depending on material flow, the Power-Pin can stand freely in a room or be placed against the wall.

Dowel Insertion:

The Power-Pin can drive in both pre-coated dowels and standard wooden dowels measuring 30mm, 35mm and 40mm in length. For Standard wooden dowels, glue is injected into the holes prior to insertion. With the optional second step conveyor, the change from 6mm to 8mm dowels is done in minutes.

Intuitive Software:

Holz-Her’s Campus NC-HOPS software comes as standard on every Power-Pin. With simple operation at the forefront of its design, the software allows the user to programme individual components and adapt them quickly using simple macros. It’s EasySnaps parametrically programmable feature also guarantees the upmost precision, whilst the complete machining operation is displayed in a 3D format on a 21.5” touch screen display for ease of use.

Multi-field processing:

The large-area support table enables multi-area loading of up to four components at one time. The intuitive clamping concept – which automatically adjusts depending on the material being processed – ensures that longer components up to 2600m can be loaded and uploaded quickly and safely. It also makes for simple operation when running large batch and recurring compo-nent sizes.

Dowel Unit:

For short machining cycles, the dowelling unit can be variably off-set in 32mm increments up to 192mm, with the software automatically calculating whether simultaneous dowelling and drilling is possible. Depending on the number of holes and dowels, this can result in a 20% reduction in time.

Automatic programming:

For simple machining on the Power-Pin Dynamic, automatic program selection measures the width of the workpiece via a light barrier. When a pre-programmed workpiece width is detected, the appropriate program is automatically loaded. Additional VISE LED position indicators also simply operation further. On the Classic, the drilling depths and height can be set manually with two pre-defied drilling depths.

Energy saving credentials:

Eco Mode offers a time controlled shutdown to save energy and reduce running costs.

Drilling Unit:

The 3-fold drilling unit allows for a variable speed of 2750mm – 4000 min and individually pre-settable drilling spindles in a 32 mm grid – ideal for carcass construction.

Paul Nightingale, National Sales Manager, Holz-Her UK: “The new Power-Pin offers vast time savings as the horizontal drilling and dowelling can be done by the nesting CNC operator whilst the next sheet is being nested. Thanks to machine’s low machine height, the operator can easily oversee the nesting process whilst drilling and dowelling in masked time – essentially completing this step without adding any time whatsoever to production.”

For more information please visit holzher.co.uk.